Corrosion

Glaze and surface corrosion

General definition of corrosion

From a technical point of view, corrosion (Latin corrodere 'to decompose', 'to eat away', 'to gnaw away') is the reaction of a material with its environment, which causes a measurable change in the material and can lead to an impairment of the function of a component or system. In geology, corrosion is the decomposition of rocks through the action of water. Such weathering processes also play a role in buildings. In medicine, corrosion refers to the decomposition of tissue. In the case of metals, chemical corrosion is particularly important. The most well-known type is rusting.

On a chemical level, this involves the release of ions of various elements such as sodium or potassium. This physically changes the optical properties of the material (refractive index) at the affected areas, causing the clouding to occur. The susceptibility to glass corrosion is influenced by the material itself (lead crystal glass, for example, is less susceptible), by the lime content and temperature of the rinsing water and by the water vapour acting during the drying process. This chemical reaction is a process in which an atom, ion or molecule releases electrons. We know from physics that water in combination with pressure is a powerful carrier of electrons and therefore this factor turns every standard dishwasher into a kind of electron catapult. Every dishwasher definitely increases the oxidation number and distributes the electrons over the bodies and substances placed in it. Professional chefs know that a single kitchen knife with a steel blade or a metal peeler favours the formation of rust film on high-quality stainless steel cutlery. Porcelain with less hard surfaces is also susceptible to such corrosion processes.

Corrosion of ceramic surfaces (glazes)

The surfaces of glass and ceramic materials can also corrode, i.e. be subject to an oxidation process.

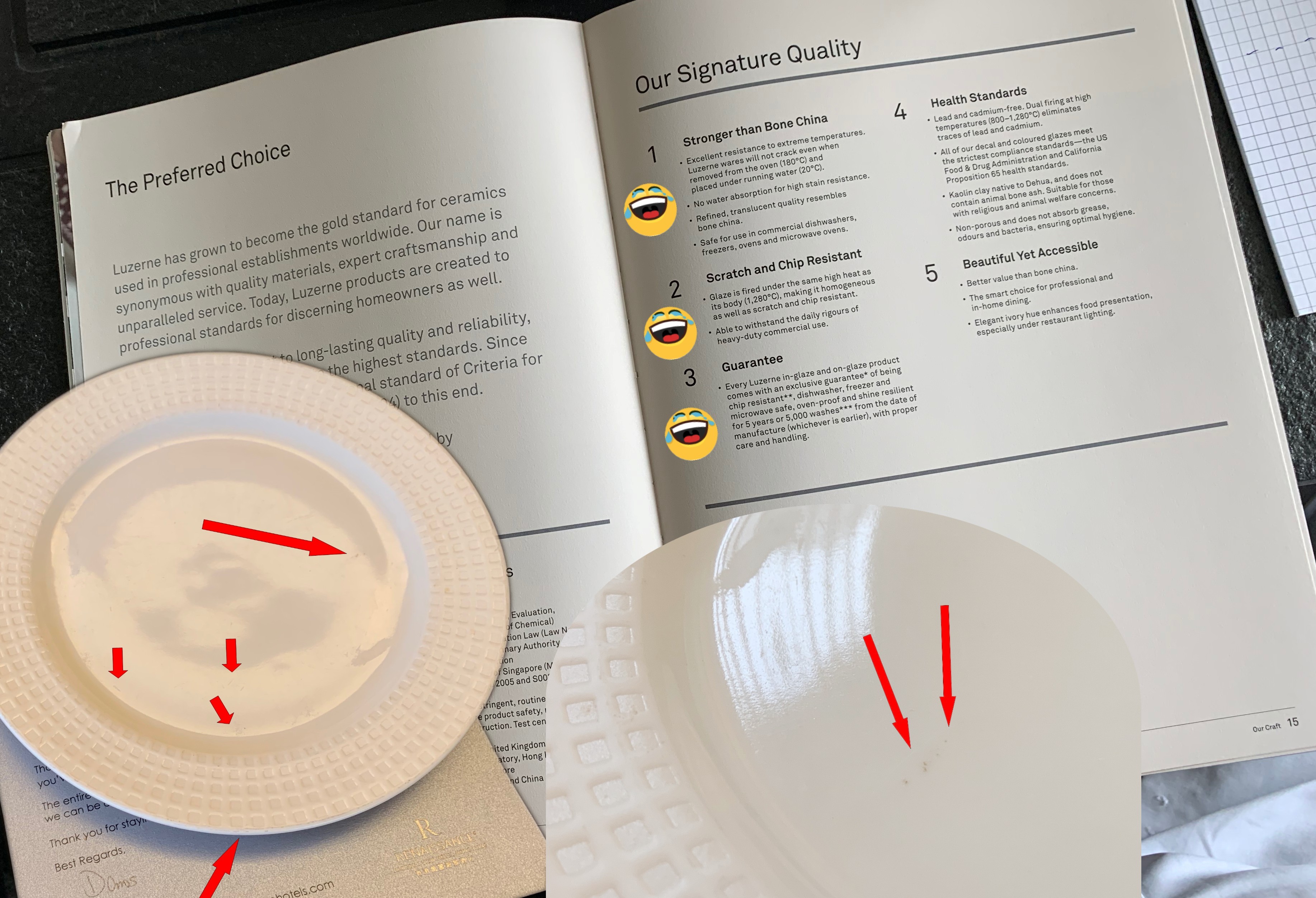

In particular, bodies with a claimed physical load-bearing capacity, i.e. breaking strength, cannot be fired at 1,350 °C due to the addition of reinforcing additives. A number of mainly English manufacturers use the designation "Durable" or "Resistant". In such cases, be sure to ask about the firing temperature, otherwise you will end up like this Marriott Hotel (picture above).

Glazes with a Mohs hardness of 6 and higher are hardly affected by corrosion. They contain a higher proportion of quartz and/or the addition of aluminium oxide. These additives in a glaze require a higher firing temperature due to the higher melting point and are not possible with types of ceramic such as Stoneware, Durable and many others. These usually have a hardness of 5 and are more susceptible to glaze corrosion.

Ceramic types susceptible to glaze corrosion

In our product information on the "Firing & Kiln" page, we have illustrated the dependence of the hardness of a ceramic body on the firing temperature of its hard firing. In doing so, we emphasise the conclusion that all ceramic qualities fired below 1,300 °C are definitely not porcelain in our understanding and opinion and do not deserve this quality designation! A hardness of 8 Mohs and more is currently (as of 07/2019) not possible below a glost firing of 1,300 °C! This statement applies in particular to the following types of ceramic products:

- Durable China (primarily China)

- Diamond China

- Dynamite China

- Elegant China (primarily Indonesia)

- Magnesium porcelain

- Bone China

- New Bone China

- Fine China (primarily Indonesia)

- High Fine Bone

- Ivory China

- Dura Cream

- Luxor Cream

- Stoneware

- Earthenware

- Fine soils

- Fayance

- Alumina porcelain (below 1,320 °C firing temperature)

- et al.

We also explain why so many fancy names are currently being "cheated" on our "Firing & Kiln" page. This circumstance brings with it a relatively new or modern phenomenon, namely the wear of glazes due to abrasion and corrosion. We report here on the three main symptoms of poor glaze hardness.

Glaze corrosion due to chemicals and detergents

The chemical composition of the detergent used also has a significant influence on glaze corrosion. In commercial use, especially in large warewashing systems (e.g. in hospitals), thermal cleaning is often replaced by chemical cleaning for cost reasons. This use of "harsh" chemical detergents quickly "blinds" all glass and porcelain and "dulls" the surfaces. Without exposure to chemicals and quartz crystals, porcelain retains an "eternal" lifespan, i.e. it does not age and does not change its consistency, shine or brilliance even after many years and decades.

Example - Glaze corrosion

What has happened? Aggressive washing-up liquid, which is mainly used for hygienic cleaning in the post-drying process, chemically attacks the glaze and causes surface corrosion, which ultimately leads to complete wear. The manufacturer of this product calls it "bone china" and guarantees that it is harder than normal porcelain. We say: This is nonsense and prove it with the example photo above!

Apart from the fact that glaze corrosion is a visual disaster and is perceived by guests as "dirty & grubby", the porcelain or ceramic can quickly lose its suitability for use as a food contact item.

Therefore the urgent advice: Corroded crockery must be replaced immediately!

Glaze corrosion - defect or characteristic?

However, it remains to be seen whether this type of corrosion is a defect in the porcelain. On the one hand, there is a whole range of manufacturers who sell this type of ware on the market - sometimes with great success - and on the other hand, manufacturers can conceal the optical signs of corrosion well by using large decorative areas and coloured porcelain, thus visually prolonging the decomposition process. Perhaps this explains why - especially among the brand names - the richness of decoration is so varied and white porcelain is so rare. Ultimately, only the white plate - like the white towel in the bathroom - is a clearly visible guarantee of hygienic cleanliness for the guest.

Above all, however, porcelain corrosion is favoured by the use of very strong chemical detergents, which ultimately corresponds to a failure to use the product as intended.

If in doubt, please explicitly request hard porcelain to completely rule out the risk of porcelain corrosion.