Shipping Carton

Dispatchable packaging from Holst Porzellan

DIN ISO 2248

Consignors consistently apply loads to the packaging in accordance with DIN ISO 2248.

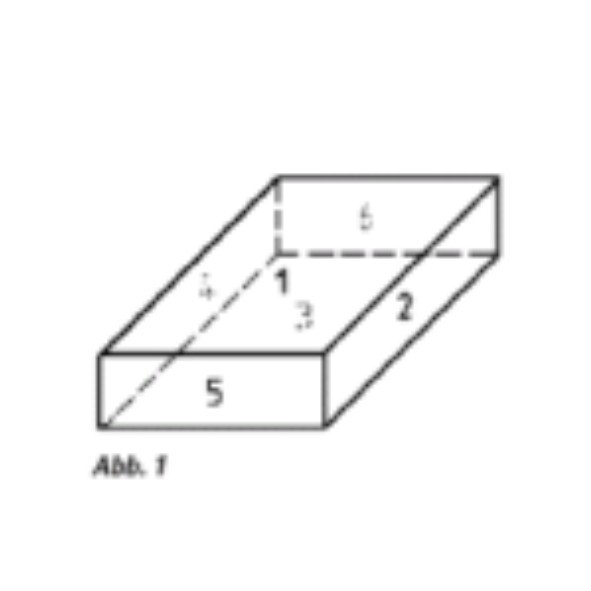

Cuboid packages (Fig. 1)

The package must be placed in the intended transport position. If the transport position is not known, the manufacturer's seal (factory edge), if present, must form the right vertical edge of the surface facing the observer.

A surface faces the viewer. The top surface is labelled "1", the right-hand surface as seen from the viewer is labelled "2", the bottom surface is labelled "3", the left-hand surface is labelled "4", the surface facing the viewer is labelled "5" and the surface facing away from the viewer is labelled "6".

The edges formed by the faces of the sample are labelled using the numbers for the faces that form the edge.

(Example: faces 1 and 2 form edge 1-2) The corners formed by the faces of the sample are designated by using the numbers of the faces in question. (Example: The faces 1, 2 and 5 form the corner 1-2-5)

(Fig. 1)

(Fig. 1)

Brief description of the procedure

The package is lifted above a rigid, flat surface and dropped freely onto this surface (impact surface).

Impact surface

The impact surface must be horizontal, flat and sufficiently solid or rigid so that it neither moves nor deforms under the test conditions.

Drop height

The DIN specifies guide values according to the mass of the package. Ergonomic aspects were assumed for manual handling.(DIN 55439)

up to 10 kg 80cm

10 to 20 kg 60 cm

20 to 30 kg 50 cm

30 to 40 kg 40 cm

40 to 50 kg 30 cm

50 to 70 kg 20 cm

Test sequence (10 times free fall)

1 x corner * 3 x edge * 6 x surface

Cuboid packages

Corner case 2-3-5

Edge case 2-5,3-5, 2-3

Area case 5, 6, 2, 4, 1, 3