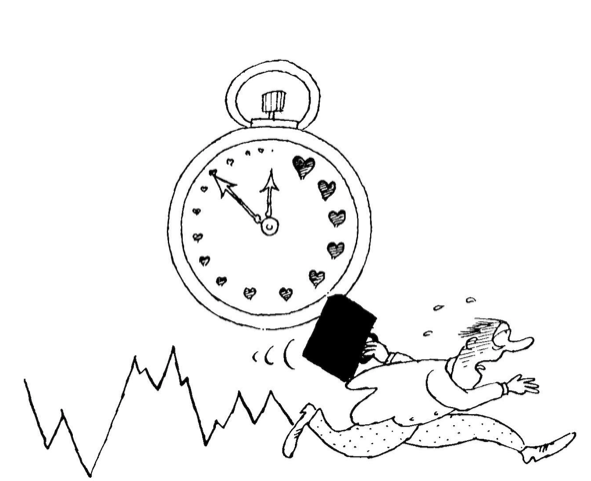

Time

Time - an important raw material in the production of porcelain

Quite simply put, porcelain - like all other ceramic tableware - is the result of mixing different materials which are fired into a solid under the influence of thermal energy. In fact, the time factor plays a significant role in the quality, durability and longevity of the final product. Many defects in porcelain are due to a lack of time.

Similar to a yeast dough, the raw materials need a certain amount of time after they have been brought together to bind and evaporate. After shaping, the green body needs time to dry until it has a workable consistency. The glazes need time to release the contained oxygen after mixing. In the various firing phases, the raw materials need time to release their large number of physical and chemical reactions. Kaolin, feldspar and quartz need time to form mullite in the embers of the kiln.

The high level of industrialization by means of NC-controlled cycle lines, isostatic presses, fast firing kilns, etc. as well as rationalization measures serves primarily to reduce or optimize the following

- the shares of human work performance

- direct energy costs

- Raw material costs

- Space and processing costs

In the many stages of production, however, this "optimization" is at the expense of the time that porcelain simply needs to mature. May many manufacturing processes today be "better" than in the past - porcelain is not!

We end this section with the words of the owner and chef of a restaurant well-known in East Westphalia. "...the brand porcelain, which still dates from my father's time, simply cannot be broken. The quality of today's repeat purchases can really no longer be compared with it..."

Holst Porzellan makes every effort to have the tableware made where the important components of production - and the people who make it - still get their time.