Glazing line

The glazing line is the fully automated process of dip glazing. This process is often combined with a fully automatic production line, making it the most modern way of producing porcelain. In traditional porcelain production, on the other hand, hand glazing is usually used.

How the glaze line works in porcelain production

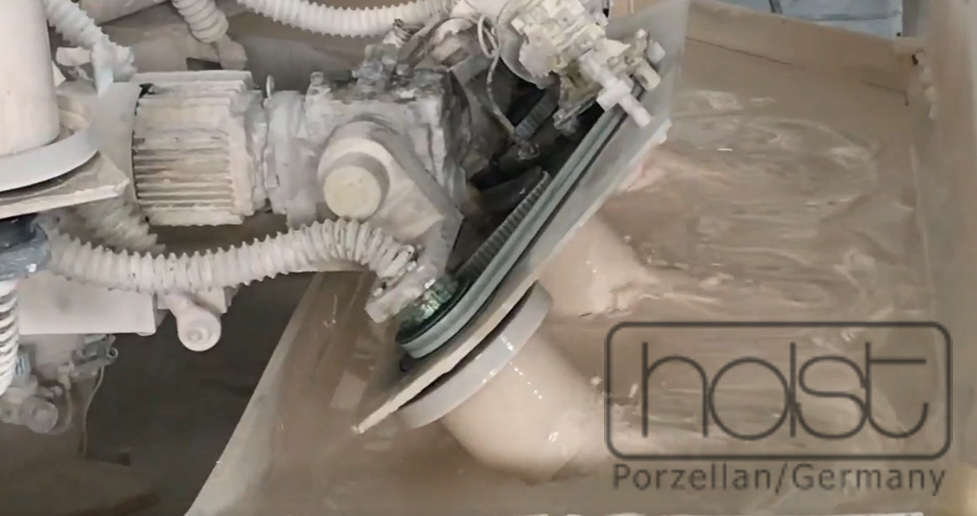

1 First, the unglazed porcelain bodies (shards) are placed on a machine and fixed with a suction system. Now the shards are ready to be glazed.

2 To prevent defects of the glaze, the shards are dipped into the glaze while rotating. It is perfectly sufficient for the body to spend just a few seconds in the glaze bath.

3. the porcelain bodies are now removed from the glaze. During removal, it is very important that the porcelain body remains in motion again to prevent so-called glaze noses.

Here we explain the traditional method of dip glazing.