Assembly lines

(Rights: Julius Lippert GmbH, Pressath)

A cycle line in the porcelain industry is an NC-controlled production unit used in industrial mass production. It represents a specialization of flow processing and combines several production stages in one flow. Successive work processes are linked together and are arranged in such a way that they allow an optimal sequence of the work process. The transport of the production goods between the individual production points is carried out by means of interlinked conveyor systems, e.g. conveyor belts.

If an automated linking of the production stations takes place, one speaks of a (rigid) transfer line, the production process is fully automated. Due to the often high plant intensity, this type of production is mainly used for mass production. In spite of NC technology, the effort for a changeover to another product type is very costly. On the other hand, the variable costs can be kept relatively low (low costs of storage and transport, production and wages, little scrap and waste).

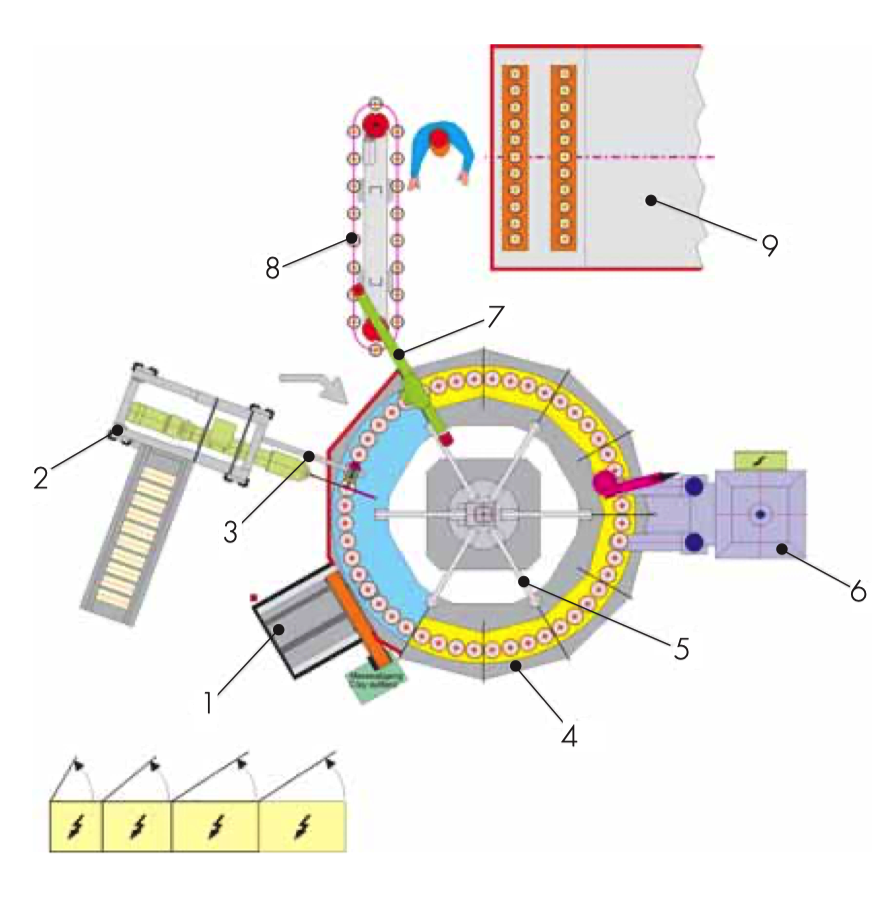

The diagram above shows a carousel cup transfer line of type P41, manufactured by Lippert, Pressarth. Despite its name it can produce many types of hollow parts, e.g. cups, mugs, bowls and bowls. The mould load of such a production unit is considerable and above all very cost-intensive. More.