1320 °C

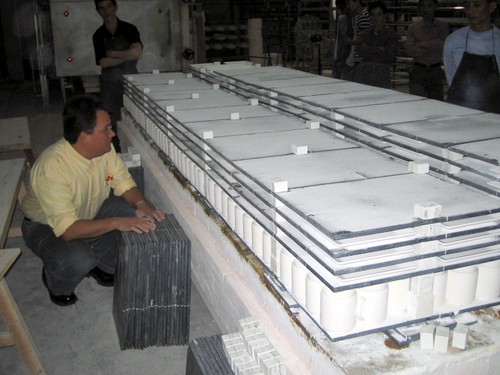

1,320 degrees Celsius and more - The guarantee for genuine hard porcelain

Personal closing words of the author

In the more than 37 years in which I have been personally involved with porcelain, occasionally neither my training nor the more than 60 years of business experience have been able to help me determine genuine hard porcelain beyond any doubt. Some very clever manufacturers have actually succeeded in submitting even us inferior quality. We have paid dearly for the resulting damage - I personally have.

In our search for the ultimate seal of quality, the guarantee mark and the largest common multiple, the solution was so simple that it was almost too easy and quickly forgotten.

It is the firing temperature!

The distinctive point where feldspar, clay, kaolin and quartz sinter through and become durable, good quality porcelain is

> 1.320 °C

Everything that is fired at lower temperatures is not hard porcelain. A Mohs hardness of > 7 (DIN-EN-101) or > 6 (DIN-EN-15771) cannot be achieved below 1,320 degrees Celsius. A body fired at 1,240 °C and its glaze may be "durable" and extremely resistant to mechanical impact, but its surface is soft like potash glass with a hardness of < 5 (DIN-EN-101) or < 4 (DIN-EN-15771). Each rinse cycle significantly reduces the life of such a plate. Chemical post-drying, as used in large dishwashing lines, makes the shards corrode unsightly and unusable within a few months.

When you buy porcelain, make sure that the firing temperature is at least 1,320 degrees Celsius, then you will have something for a long time.

Your

Knud Holst