Fuels

Fuels for the production of porcelain & ceramics

Energy source quality feature

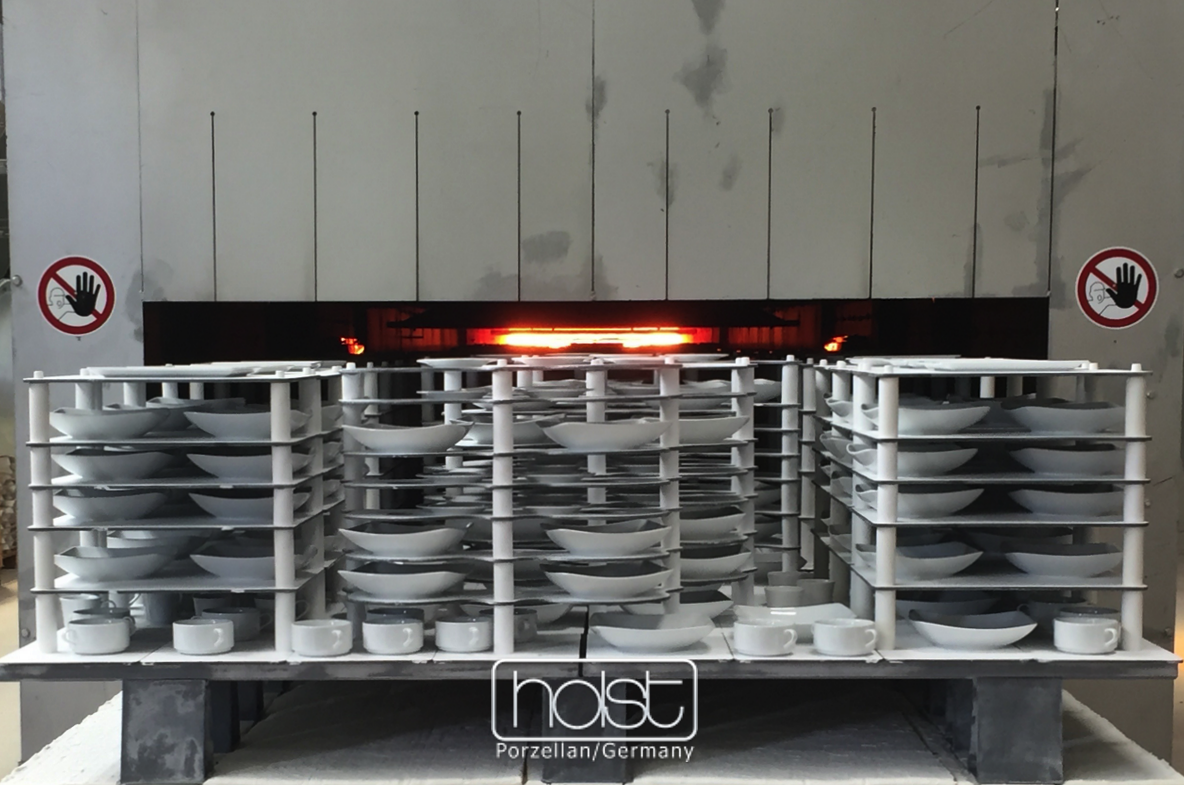

Please clarify the difference between a cooked salmon and a smoked salmon. The way the porcelain is fired has just as great an influence on the quality of the end product. Our picture (above) shows a traditional coal stove as it is still used today in parts of China, Vietnam and Thailand. The sight is reminiscent of the film Titanic, in which a troop of strong men constantly shovels coal into the fire in the belly of a ship; the same is actually true of a tunnel kiln powered by coal.

In the same way that beechwood smoke lays down on a ham, burning residues beat on the white porcelain. Some of these are visible, but worse are the invisible residues such as lead or cadmium, which could penetrate the glaze in the flame mist. It is therefore wrong to assume that white porcelain - without decoration - is always free of hazardous substances that prohibit its use as a foodstuff. During smooth firing, glazes are permeable to gases and therefore susceptible to them.

Today's modern kilns are operated with gas, which emits much less carbon dioxide (Co2), but does not guarantee that it will not lead to contamination with hazardous substances.

High-quality porcelain, like all other ceramic end products, is fired "in the fire". In order to generate this fire for production, two basic components are required: A kiln and appropriate fuels. This section deals with the fuels and their influence on the quality of a tableware item. Basically we know 5 types of fuels in the porcelain industry.

- Natural gas

- liquefied petroleum gas (LPG)

- Oil

- Coal (coke)

- Electrical energy

(Source: With the friendly support of Zukunft ERDGAS GmbH, D-10117 Berlin)

Grass fuel

The above-mentioned fuels natural gas (compressed natural gas / CNG) and liquefied petroleum gas (LPG) can be summarised in view of their problems in the production of porcelain and ceramic tableware. Although the basic materials are different

- CNG natural gas: Mainly methane

- LP liquid gas: mainly propane and butane mixture

Both types of gas contain chemical substances such as halogens, chlorine and sulphur (hydrogen sulphide). The energy industry is trying to make the fuels more "biological" and is trying to increase the shares of biogas and synthetically produced gas. Such gas-fuel variations usually also bring new problems because the chemical composition is not constant. In particular, the sulphur content of the gas is difficult to control.

We quote the BFG - Bundesverband für Gasanlagentechnik - as follows.

| "... the legislator... only half-heartedly or even partially does not comply with DIN EN 589. This is the only way to explain why only the BFG, when investigating components of gas plants, now finds, in addition to the already known inexplicable amounts of exhaust vapour residues (see photo), also larger amounts of sulphur deposits (see photo) far above the permitted specifications of DIN EN 589. As a consequence, larger quantities of iron oxide have now been found (see photo), which, according to the BFG, are also due to the high sulphur content and which literally decompose the components in the gas plants...." |

This formulation explains, of course, that fuel residues alone can cause unwanted soiling due to evaporation residues on the dishes placed in the oven at any time and in an uncontrollable manner. Such evaporation residues are responsible, among other things, for the well-known "pinholes" or for the loss of the LFGB foodstuff suitability.

Fuel Oil and coal

As the firing of furnaces in the porcelain and ceramics industry has virtually died out for environmental and energy efficiency reasons, e.g.

- Germany already in the late 1980s

- China since 2016

we do not want to describe the problem of "coal and porcelain firing" in detail in our product information. It is sufficient to know that coal kilns basically required a reduction firing, i.e. the placing of the porcelain in firing capsules, because the combustion of the fossil fuels produced so many fuel residues that the porcelain could not possibly be produced in an "open oxidation firing". To our knowledge, the last coke ovens in the porcelain industry were shut down in China in mid/late 2017.

Elektrische Energie

The title alone reveals that electrical energy cannot "burn". Electrical energy is only suitable for operating radiant heaters, be they ceramic radiators, red light or infrared radiators. In commercial porcelain production, electric furnaces are not used for hard firing (glaze firing) because the use of electrical energy is too expensive and not efficient for the necessary temperature ranges of more than 1,300 °C and less than 1,500 °C.

Furthermore, it is not possible to produce ceramic tableware in reduction firing, since electric furnaces generally require an oxidation process.

Electrical firing energy in the porcelain and ceramics industry is currently (as of 2019) mostly used in so-called "onglaze kilns" (up to 900 °C) or decorating kilns (up to 1,250 °C). In a "clean" environment, electric furnaces cause the least precipitation of energy-related exhaust vapour residues and represent the "cleanest" type of ceramic firing in every respect. We know electric kilns from technical ceramics, whose temperature range extends far beyond the 1,300 °C necessary for porcelain. Spark plugs, for example, are produced in electric furnaces up to a maximum temperature range of 1,700 °C.

This gives hope that the further development of environmentally friendly electric ovens can also be used in the long term for the production of tableware.