Firing & quality

1890 - A throwback into history

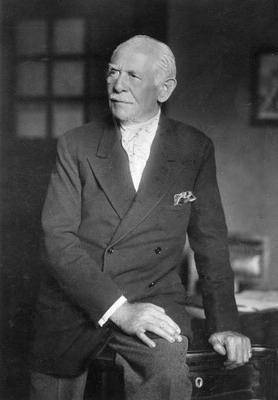

(Philip Rosenthal, Quelle: Familie Rosenthal)

After World War II, in the 1950s, the German porcelain industry in particular developed into an internationally important branch of industry. China, the world number one in porcelain, is far away and inaccessible for Europe. It is a privilege and an honor to produce porcelain and to mark it with your family name. Rosenthal, Seltmann, Vohenstrauß, Kronester, Villeroy & von Boch - behind all these brands stand entrepreneurs, visionaries and families who have built them up. Just this honour forbids, like the purity law of beer of 1516, to change anything about the noble ingredients of real porcelain. Moreover, the range of masses and additives is very limited and the wood and kaolin deposits make it a raw material-oriented industry. Whether noble brand, Bavaria Germany or Frankonia tableware, where porcelain is on, there is really porcelain in it.

1973 - The first crisis

(Porcelain factory Winterling Kirchenlamitz, Source: Family Winterling)

Between 1950 and 1972, the industry boomed in the Fichtelgebirge, creating important jobs and a solid infrastructure through ERP funds in the otherwise barren and structurally weak region. Every year the factories reach higher production volumes and there is a seemingly unstoppable and incessant growth. Until the oil crisis in 1973! There is the first infarct, which 20 to 30 years later will wipe out almost the entire industrial sector in Germany. The post-war demand is covered and the production of porcelain becomes cost-sensitive at a stroke.

1990 - The international change

In the search for ever cheaper locations for porcelain production, the European neighboring countries are being attacked like a swarm of locusts. Rosenthal over Poland, Winterling over Portugal and Hungary, Hutschenreuther over Romania and many more. If an even cheaper location is found, the production is quickly dismantled, or even better, old production facilities are simply left behind and new factories are built with plenty of subsidies from the German, or Bavarian and Thuringian state, because Germany is now also enriched with the EX-DDR factories. With less and less demand comes higher and higher production quantities. From Germany and from all over the world. In addition, the popularity of decorated porcelain is declining sharply and the variety of shapes is finding its way onto tables and tables.

Energy has become expensive, kaolin is becoming scarce and the industrial form for only one plate size costs about 14.000,-- Euro. The former brands of the past, Rosenthal, Winterling, Mitterteich & Co. are all broke, exploited as brands or sold. Brands such as Asa, Flirt, Domestic or Holst and many others create trends and are partly produced in the same factories as Wedgewood, Villeroy & Boch or Hermes. To the enormous production capacities of Europe now also Turkey and China are added. The market increases in sharpness and always new market participants from outside change the codex of this industry.

2013 - Cheating begins

At the request of European manufacturers, the European Union will impose punitive duties on porcelain from China in 2012. Porcelain from Portugal, Turkey and Poland populate the shelves at Ikea & Co. Despite global price increases and shortage of raw materials, porcelain simply does not want to become more expensive. Personnel has already been cut back, processes rationalized, but hardly any money is earned. On all sides.

The industry codex has evaporated, the industry is being robbed and copied and everyone is fighting for their own survival. The term "porcelain" has now changed so much, driven by poorly trained personnel, that today hardly anyone can distinguish or define what is actually porcelain:

- Durable China

- Diamant China

- Dynamite China

- Magnesium Porcelain

- Bone China

- New Bone China

- Fine China

- High Fine Bone

- Ivory China

- Dura Cream

- Luxor Cream

- Stoneware

- Earthenware

- Fine Earths

- Fayence

- Alumina Porcelain

- High Alumina

- and much more

The quality and properties of these types of cullet are very different, but not visible at first sight. The supposed industry expert may be able to tell from the clay produced by his snapped fingernail on a plate whether it is fired or high fired cullet. But he would lose 5 out of 10 bets. The experienced industry expert analyzes the unglazed base ring and can distinguish porcelain from stoneware by color and porosity based on the exposed shard. Provided the body is not pigmented! So he would only lose 3 bets out of 10.

In this way, large brands and windy importers alike succeed in "turning on" inferior, or at least a different type of ceramic to the dealer and the end customer. Only after repeated use does it become apparent whether or not the durability, shine and longevity of genuine hard porcelain is achieved or not.

Then often what you see in the picture above happens. The glaze is heavily corroded, cutting marks and cutlery abrasion have worn away the glaze and the plate has completely lost its beauty and hygienic properties. Its supplier, a well-known English brand with international standards, advertises this "porcelain" with the addition "... particularly durable and insensitive...".