Sintering

The term sintering in the ceramic industry is a physico-chemical process that takes place in the ceramic, porous shaped body under the influence of high temperatures and influences its structural formation. A temperature effect below the melting temperature leads to one-component reactions which, while maintaining the shape, cause the porous body to solidify. Sintering processes are extremely complex. A multitude of partly uncontrollable interactions occur between the particles, the pores, the different phases, the grain boundaries, the structural elements and the atmospheric conditions. If one considers the abundance of raw materials that can be used, one gets an approximate impression of the multitude of different firing methods.

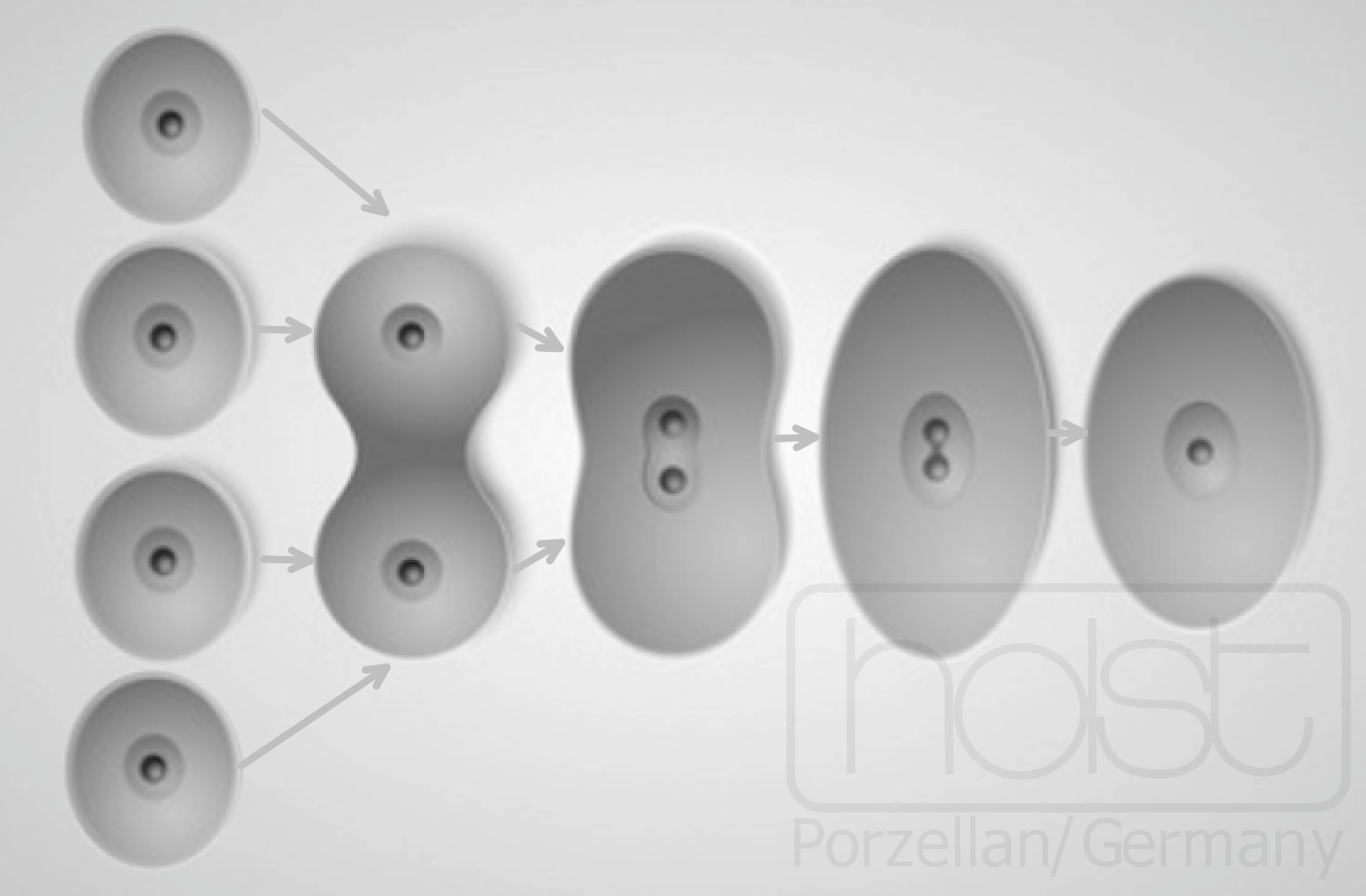

During sintering, physicochemical reactions take place in the molded body, in which the different components of the ceramic materials react very differently as they combine with each other (diagram above). Sintering leads to solidification through the fusion of the different masses.

It is only through the temperature treatment of the sintering process that a fine-grained or coarse-grained green body, which was formed in a previous process step - for example by extrusion - becomes a solid workpiece. The sintered product only receives its final properties, such as hardness, strength or thermal conductivity, which are required for the respective application, through the temperature treatment. The sintering process of porcelain generally causes a loss of dimension through shrinkage.