Oven & porcelain

Porcelain in the oven

In the technical language of porcelain, the terms "ovenproof" or "refractory" refer to the heat resistance of a product. Genuine hard porcelain or feldspar porcelain, which is fired at a temperature above 1,300 °C, is well suited for use in ovens, microwaves, combi steamers and salamanders. Other types of ceramic, such as terracotta or stoneware, are also suitable for use in ovens. Some groups of kitchen porcelain items, such as

- Baking moulds

- Gastronorm trays

- Chicken roaster

- Ramequin moulds

- Souflee moulds

- and many more.

are labelled as "refractory" by the manufacturers. If you look up the term "refractory" in a dictionary, it is defined as follows: "...refractory materials of ceramic products that are used at high temperatures due to their mechanical properties. The possible applications are determined by the softening under pressure or tension, the strength from low to high temperatures..." So there is no precise definition or even a temperature limit!

Apart from this, there are considerable differences between appliances that are labelled as ovens. In the home, ovens are generally designed for a maximum heat output of up to 250 °C. Ovens in commercial kitchens, on the other hand, can often reach 350 °C and more. These differences are also not differentiated in the definition of "ovenproof" or "refractory".

The term "fireproof" is (as of 01/2022) neither certified nor defined according to established standards. In fact, there is a type of special porcelain that has enormous properties in terms of heat resistance. However, these are special pieces such as crucibles, evaporation dishes and special laboratory porcelain, which are bred to have these properties by adding special raw materials or by changing the classic material composition (e.g. by increasing the quartz content). However, these porcelain masses and porcelain thicknesses are a far cry from tableware.

Certain article groups such as pudding moulds, ramekin moulds, baking and casserole dishes, egg pans and cocottes are produced with a thicker body thickness and therefore physically improve the general heat-resistant properties of hard porcelain and feldspar porcelain.

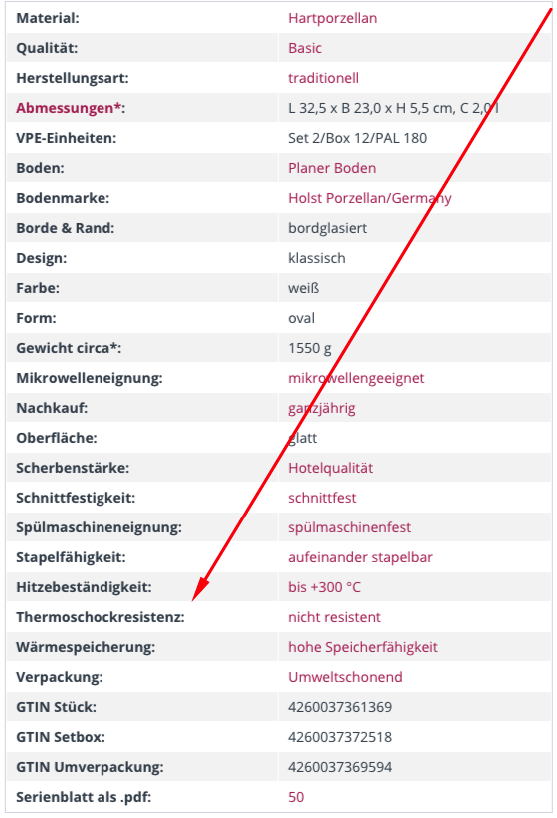

Heat resistance of Holst porcelain

Each item in our collection is specified with its heat resistance in its item passport. Due to our wide range of 6 different types of material, we cannot make any generally binding statements here about the respective heat resistance, the maximum thermal load or the thermal shock resistance of each individual item in our collection. Please therefore refer to the information in the article passport.

Heat resistance of hard porcelain in general

All types of genuine feldspar porcelain - which at Holst Porzellan include the materials hard porcelain, alumina porcelain, high alumina porcelain and ultra alumina porcelain - are fired above 1,320 °C during the manufacturing process. If you imagine that porcelain tableware made of thin and fine porcelain also has a dishwasher-safe decoration, the heat resistance of porcelain is self-explanatory. In-glaze decorations are subsequently fired into the glaze of the porcelain at temperatures of 1,100 °C and above. This means that virtually any white feldspar porcelain can withstand this temperature increase of up to 200 °C. It just depends on the correct dosage of heating and cooling.

However, ovens do not have this technology and no user wants to heat their crockery for 4 to 6 hours in one firing curve!

The lowest common multiple for undecorated, white feldspar porcelain is that it can be used in the oven up to 200 °C without any problems, excluding thermal shock. No generally applicable rule can be derived for coloured or decorated porcelain due to the large number of different types of decoration.

Instructions for using porcelain in the oven

- Only use porcelain labelled "ovenproof" or "stoveproof".

- Pay attention to the temperature resistance specified by the manufacturer.

- Avoid thermal shock.

- Do not hit hot oven porcelain

- If in doubt, test the temperature resistance of the item yourself when empty

Product knowledge - A request to our readers!

Since 1998, we have been cultivating our product knowledge out of a passion for porcelain and the endeavour to share our knowledge about this beautiful and exciting material. In more than 20 years, our information pages have grown into a free online encyclopaedia of porcelain knowledge and now serve as a helpful reference work for dealers, end customers, vocational schools and even competitors. In times of increasingly important reviews on the Internet, we therefore ask you to write us a small review on Google. This will help us to address topics that have not yet been dealt with and to constantly revise this knowledge database. Thank you very much.