Determination of materials

Determination of the material type of porcelain and ceramic

Determining the quality class of a piece of tableware - in this case "the plate" - is not always easy, even for a specialist. In this section we intend to show some generally valid distinguishing features. They are relatively easy to handle and provide initial information about the type of body and its glaze. When determining a ceramic grade, there are basically two different types of characteristics.

- The visible features

- The invisible features

The determination of the invisible characteristics and special peculiarities of a product requires a chemical-mineralogical examination, for which we also need to call on laboratory technical assistance. For this purpose, we turn to specialized universities, officially accredited testing laboratories or to the TÜV and other institutions. Therefore we limit ourselves here - for the determination of porcelain - to the visible characteristics.

Very similar!

Seen from above, a ceramic plate can resemble a porcelain plate like an egg. There are no visible differences on the glazed surfaces.

According to the scientific definition, porcelain is transparent. Even a rating includes the transparency of a piece of pottery. However, porcelain - and especially hotel porcelain - cannot be determined without doubt by its transparency in daylight. Neither the Bauscher plate (in the picture above), nor Holst Porzellan nor any other brand can be determined in this way. On the page "Transparency" we explain this property in detail. Please watch the following video on the subject of "Perfect determination of the quality class 'porcelain' by the property of transparency".

Density - The sound test

The density of a shard can only be determined to a limited extent by its timbre. The trained ear is able to distinguish between ceramics, earthenware, stoneware, etc. fired at low temperatures and porcelain by snapping on a plate rim. However, as our video (picture above) clearly shows, the tonal colors for a piece of pottery fired in a cookie firing above 1,300 °C, as it can occur with fine ceramics or soft porcelain, are very similar, even almost the same as porcelain.

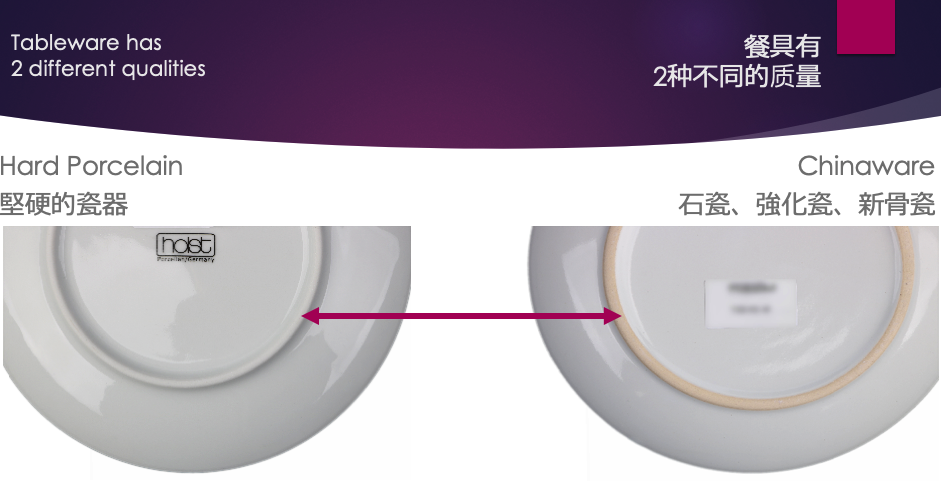

Body colour - the visual test

The visual test to differentiate between porcelain and other ceramic grades must be carried out using an unglazed area. This is usually the unglazed base ring. The unglazed base ring shows the real body as it is. A body fired with 50% kaolin (and more) is bright white and has the same color as the glaze. The glaze is transparent. Provided, of course, that the glaze has not been stained with a red, blue, black or any other color. If the body shows a different color than in the picture above right, it is not high fired hard porcelain! The commercial usability is then already with 90% certainty considerably limited.

There are manufacturers who "hide" their cullet by using a firing process that also glazes the bottom ring (adjusting ring). This is particularly noticeable with some Vitreous porcelains. If the bottom ring is glazed, the layman has no chance of determining the quality class of the ceramic himself. However, we can assure you that according to scientific and mineralogical teaching, this "vitro-porcelain" is only an imitation of porcelain. For this reason alone, further tests are basically unnecessary.

Porosity - the weight test

The less absorption a cullet has, the denser and higher it has been fired and the less porosity it has. From physics we know: The denser a mass, the higher its specific weight. This, by the way, explains why real hard porcelain is always heavier than most tableware for the home. High-fired fine ceramic - as in our video above - is always lighter than hard-fired feldspar porcelain. This is due to the white- or yellow-burning clays that replace the kaolin. The layman can only succeed in determining and differentiating between ceramic grades by lifting a plate in direct comparison, namely by directly comparing a porcelain plate and a ceramic plate of equal thickness. A professional can immediately tell whether he is holding a ceramic plate or a porcelain plate in his hands.

Score hardness - the cutting test

A very precise determination of the quality class can be obtained from the "scratch test" according to Mohs. According to the "new" classification of the mineral hardness according to Mohs (DIN-EN 15771), commercially available cutlery has a hardness of 3, maximum 4. If it is possible to scratch the glaze with a (not brand new!) knife of any cutlery series that has already been rinsed several times, it is not hard-fired porcelain. If you use this test to make a purchase decision and do it in a store or at a trade fair, please be fair and do the scoring test at an "inconspicuous" place on the underside of a plate.

Conclusion

The determination of the grade of a tableware item should not be made directly by a single one of the above methods. The production of ceramic articles takes place in too many countries with partly very different methods, raw materials and processes. Currently, a lot is also tried, cheated, imitated. Or uneducated market participants refer to the customs tariff classification by using the term "porcelain" for an inferior material.

- Light test

- Sound test

- Visual test

- Weight test

- Cutting test

In combination, these 5 determination methods are very precise. However, the safest way to determine porcelain as "porcelain" is a written confirmation - (catalog liability) - from the seller. If you have a firing temperature of more than 1,320 °C and a kaolin content of more than 50% guaranteed, nothing can happen.