Oven resistance

Oven resistance - another term without a standardized unit

In the relevant technical literature one looks up the definition of a fire resistance of porcelain and ceramic tableware without success. Even the definition according to Hans Friedl is more than poorly. A lot of text, but in the end the reader is hardly any smarter. It becomes much more detailed when one studies the publications of Prof. Dr.-Ing. Hermann Salmang, who, with his habilitation "Feuerfestigkeit der Tone" in 1925, at least defined the technical requirements of a "refractoriness to fire" in concrete terms. Prof. Dr. rer. nat. Horst Scholze, 1971-1986 Director of the Fraunhofer Institute for Silicate Research in Würzburg, then assigned measurable values and quality levels to the term. Unfortunately, however, all of them apply mainly to the field of technical ceramics and do not apply to the tableware segment.

Rhetorical requirement of oven resistance

The term resistance is preceded by the word oven, i.e. the place where tableware is to be given a certain form of resistance. Unfortunately, most manufacturers of ovenproof tableware fail to define "the oven" more precisely.

Under the aspect of a missing standard we define as follows

By ovenproof porcelain we mean articles made of high fired hard porcelain, whose thermal resistance has been increased by the addition of a higher proportion of quartz in the basic mass and/or also special recipes made of silicates and other mineral raw materials and are therefore particularly suitable as cookware for the preparation of food under high heat. With such cookware it is also necessary to adjust the composition of the glazes of the body.

Ovenproof harnesses are not suitable for direct exposure to fire and flame!

Ovenproof tableware from Holst Porzellan

Many manufacturers give their ovenproof tableware imaginative names such as Lucifer, Pyroflam, Ceratherm and others, which are all ultimately intended to create an association with heat. With us this simply means ovenproof or fireproof. Concretely, with the name "ovenproof" we give our porcelain and ceramic tableware

- by adding a higher proportion of quartz in the body

- a reinforced wall

- and a plane bottom

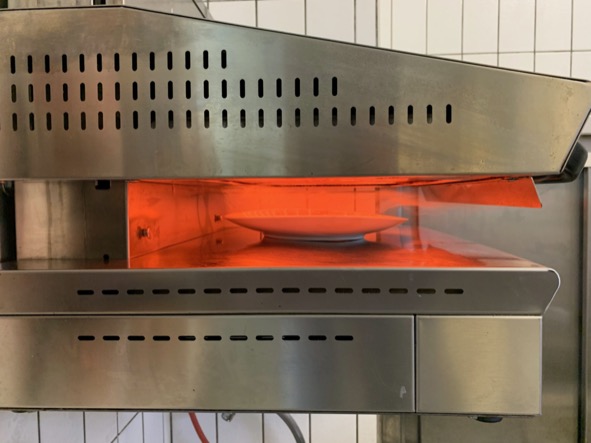

a particularly good application property for the preparation of food in ovens, convectomats, steamers, superheated steamers and salamanders, without direct flame action on the respective article In accordance with our quality standards, we distinguish five different materials in the current collections

- High Alumina Porcelain, ovenproof up to 350 °C

- Alumina Porcelain, ovenproof up to 350 °C

- Hard porcelain, ovenproof up to 300 °C,

- Durable, ovenproof up to 220 °C,

- Ceramics, ovenproof up to 250 °C.

The property of oven resistance refers to the use of porcelain as cookware in

- conventional ovens in household kitchens

- Electric or gas powered gastronomy ovens (not preheated)

- steamers, hot steam ovens and convectomats (not preheated)

- Salamanders with top heat (not preheated)

Please note that neither "fireproof" nor "ovenproof" covers resistance to thermal shock! To ensure even heat transfer, ceramic cookware and porcelain should not be placed in the oven on grids. The use of porcelain in the pizza oven is subject to special conditions and requires further explanation.

Guarantees & conformity for oven resistance

According to applicable laws and regulations of the European Union, we are obliged to issue a legally valid declaration of conformity for our goods that are intended to come into contact with food. As most of the orders we receive consist of a combination of different types of porcelain (see list above), for technical reasons we are unable to issue a separate declaration of conformity for each individual item.

Apart from this, the provisions of "oven resistance" are subject to a variety of criteria and factors that cannot be specifically proven or disputed by any of the parties involved (customer & manufacturer) in the event of a dispute. For example, cold or frozen contents in a porcelain vessel can massively restrict the oven stability (see thermal shock). Ovens with digital temperature measurement do not usually display the temperatures of trays, shelves or stone floors, which can be considerably higher than those shown.

Defects in use that have caused invisible hairline cracks or microscopic fractures can also lead to a massive reduction in oven strength.

For this reason, we follow the principle of the "lowest common multiple" in our declarations of conformity - just like car tyres, for example - and guarantee an oven resistance of 180 °C, i.e. 80 °C more than the boiling point of water, as part of our product liability. An "S tyre" - approved up to 180 km/h - does not fly apart at 185 km/h.