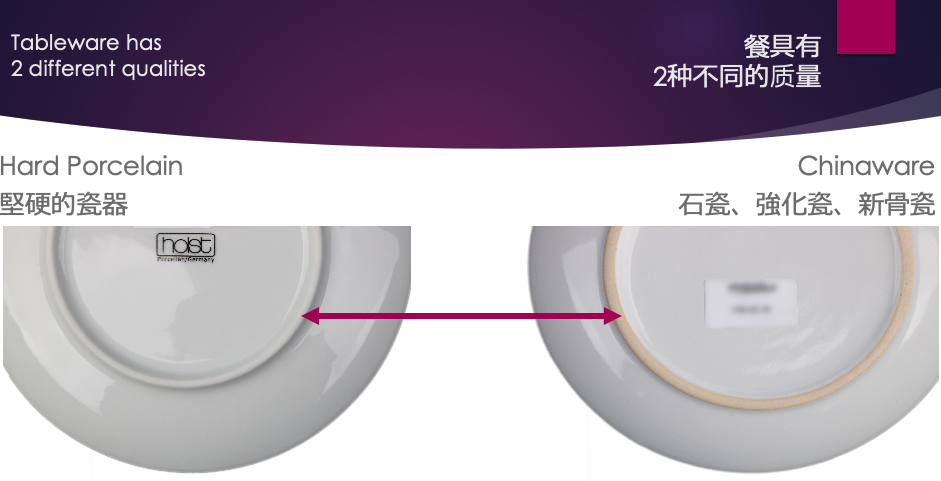

Ceramics

Although porcelain for the kitchen, table and dining table belongs to the silicate ceramics category due to its mineral origin, it is subject to clearly defined standards of quality and properties when labelled as "porcelain". The main differences lie in the use of kaolin as the moulding raw material and the firing temperature above 1,320 °C. Only in this combination do the body and glaze mature into the unique material porcelain, which is not only superior to ceramics in terms of durability and stability, but above all guarantees the avoidance of health hazards.

Harmful substances in ceramic crockery

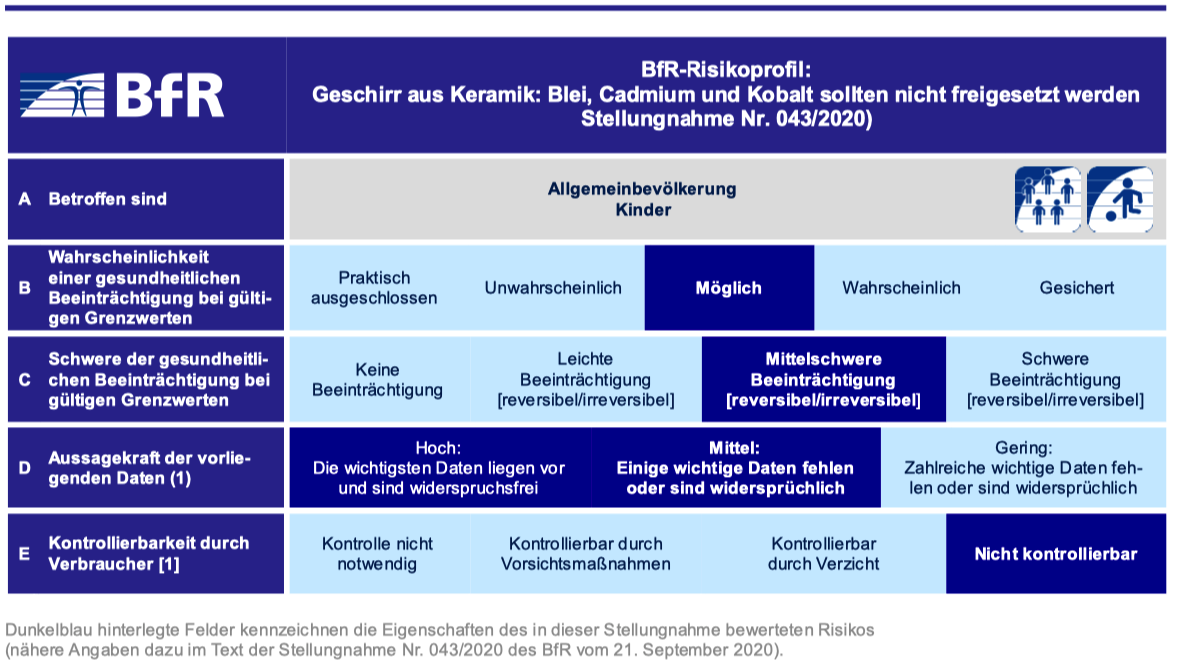

Report of the Federal Institute for Risk Assessment 043/2020 of 20/09/2020

Glazes and decorations on ceramic crockery - for example earthenware or porcelain - sometimes contain heavy metals such as lead, cadmium and cobalt. These substances can leach out of the ceramic.

This process is known as element permeability. The quantities released into food depend on various factors: the quality of the glaze, the temperature at which the ceramic was fired, the type of decoration applied, the food (e.g. acidic foods) and the duration of contact. The limit values for the release of lead and cadmium are regulated by the European (Ceramics) Directive (84/500/EEC). This is currently being revised by the European Commission. No release limit value is specified for cobalt in the aforementioned directive.

Current data from the monitoring authorities on the release of lead, cadmium and cobalt from ceramic plates show that high quantities can pass into food. However, the German Federal Institute for Risk Assessment (BfR) believes that everyday products such as crockery should not contribute to consumers' intake of heavy metals. For this reason, the BfR has derived the amount of lead, cadmium and cobalt that can be released from ceramics without any health risks being expected. The BfR refers to this as the tolerable area-related release quantity. To calculate this quantity, the Institute relies on the available toxicological studies in order to first determine a toxicologically justified release value. In addition, the state of the art in terms of analytical detection limits was taken into account. The BfR then compared the tolerable area-related release quantity with the existing limit values of the Ceramics Directive.

The result: The new tolerable area-related release quantities derived by the BfR are up to 70 times (cadmium) and 400 times (lead) below the currently valid limit values. The tolerable area-related release quantities derived by the BfR would lead to a significant reduction in the potential exposure of consumers to these heavy metals. The BfR therefore recommends using significantly lower tolerable release quantities than the limits specified in Directive 84/500/EEC when assessing the elemental reliability of ceramic products. Children ingest cadmium daily from other sources (food, toys, house dust, etc.) and thus very quickly reach the tolerable weekly intake (TWI) of 2.5 micrograms per kilogram (kg) of body weight. The lead intake from these sources is also very close to the tolerable upper limit of 0.5 micrograms per kilogramme of body weight and should not be additionally burdened by ceramics, especially in children. The BfR advises this in particular with regard to the sensitivity of children and recommends that manufacturers pay particular attention to low release quantities in ceramic tableware for children.

In the opinion of the BfR, the (Ceramics) Directive (84/500/EEC) should at least be extended to include the element cobalt as part of the revision. Furthermore, in the BfR's view, the test conditions prescribed in Directive 84/500/EEC from 1984 hardly correspond to the actual use of ceramic tableware. For example, the effects of short-term contact, heating, heating in the microwave, hot filling or years of use of crockery are not taken into account. In the interests of a meaningful risk assessment, the BfR recommends using application-orientated test conditions for the tests on element reliability.

Glazes and decorations on ceramic products may contain heavy metals such as lead, cadmium and cobalt. On contact with food, these substances can be released from the ceramic and absorbed by humans. The absorption of heavy metals can cause health problems. In addition to the quality of the glaze, the quantities of heavy metals transferred from the ceramic to the food depend largely on the temperature at which the ceramic was fired, the type of decoration applied, the type of food (e.g. acidic foods) and the duration of contact.

You can access the entire report online via the BfR.

The other distinguishing features of ceramic vs. porcelain

We have listed a large number of commercially available ceramic tableware in our product information on types of ceramics and explained the distinguishing features already known there. However, due to the different raw material compositions, firings and firing temperatures, it is almost impossible to derive generally binding quality differences that are valid for all types of ceramics. However, it can certainly be stated that, in contrast to porcelain

- high-quality kaolin was replaced by lower-quality alumina

- a ceramic body has a higher porosity

- the ceramic has a lower density

- the ceramic shard lacks the reinforcing needle mullite

- Ceramic has a higher absorption

- => as a result, the ceramic generally has a lower physical stability

- the glost firing (glaze firing) of the ceramic takes place well below 1,320 °C

- the ceramic glaze is fired lower than the body in dual firing

- Ceramic glazes often contain lead, engobes, boron, salt or frits

- => as a result, the ceramic generally has a lower hardness

Admittedly, there is a more stable ceramic than porcelain (e.g. Vitreous or Durable). However, both lack glaze hardness and therefore, above all, corrosion resistance. The lack of a property, i.e. physical stability or lower hardness, already considerably limits the usability and service life of the crockery. Extremely important in commercial use.

Recommendations for purchase

Porcelain is not only risk-free in terms of harmful substances and health, it is also more stable or harder, or more stable and harder. Conventional hard porcelain is only surpassed by special developments such as our Alumina porcelain and High Alumina porcelain.

We explain what you should look out for when buying porcelain and how you can usually determine porcelain yourself on our porcelain determination page.

Our promise

We at Holst Porzellan not only have our porcelain tested for the current pollutant emission values in accordance with the applicable LFGB, but have also been testing it for cobalt and other hazardous substances for many years - long before this report by the Federal Institute for Risk Assessment. More.